QUALITY ASSURANCE

Quality

Quality

For over 65 years Tool Specialties Company has been committed to manufacturing the highest quality of tooling for our customers. We follow the industry’s most stringent quality standards and utilize advanced technologies and equipment to guarantee accuracy of our tooling.

Design Approval

Our design team of experienced engineers, designers, and die makers partner with our customers at the initial concept stage to develop solutions to any manufacturing challenges. Using the most advanced technology and design software we offer Die Simulation to validate tooling designs and eliminate potential problems saving our customers time and expense.

Manufacturing

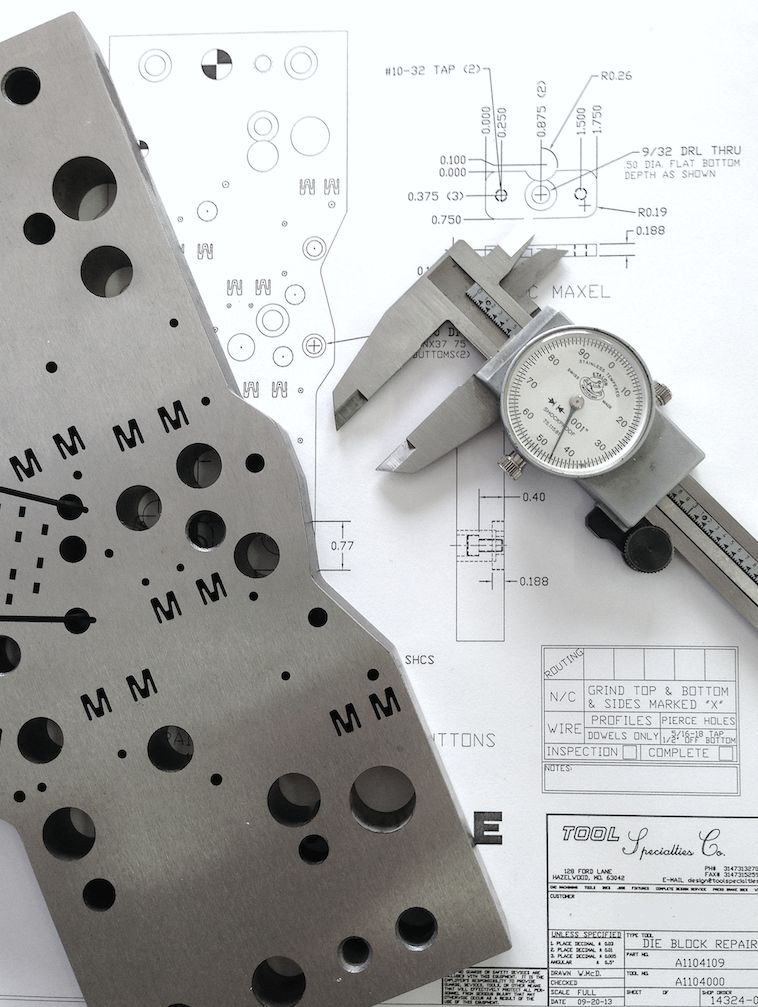

After our design team and our customer have validated the design concept the tooling is manufactured to Tool Specialties Company stringent build standards. Our die makers utilize their skills and the most advanced technology and equipment to manufacture the tool to our customer’s exact specifications. Throughout the entire manufacturing process all components of the tooling are quality checked against the design requirements following the standards of our quality assurance program to guarantee accuracy.

Quality Assurance

Tool Specialties utilizes the most advanced quality measuring technology combined with our Quality Assurance Program that is monitored and updated through ISO 9001:2015 standards. We inspect all parts throughout the process and guarantee 100% accuracy to our customer’s specifications.

Every project that Tool Specialties Company is involved in is manufactured to the highest quality standards ensuring that we meet or exceed our customer’s expectations.